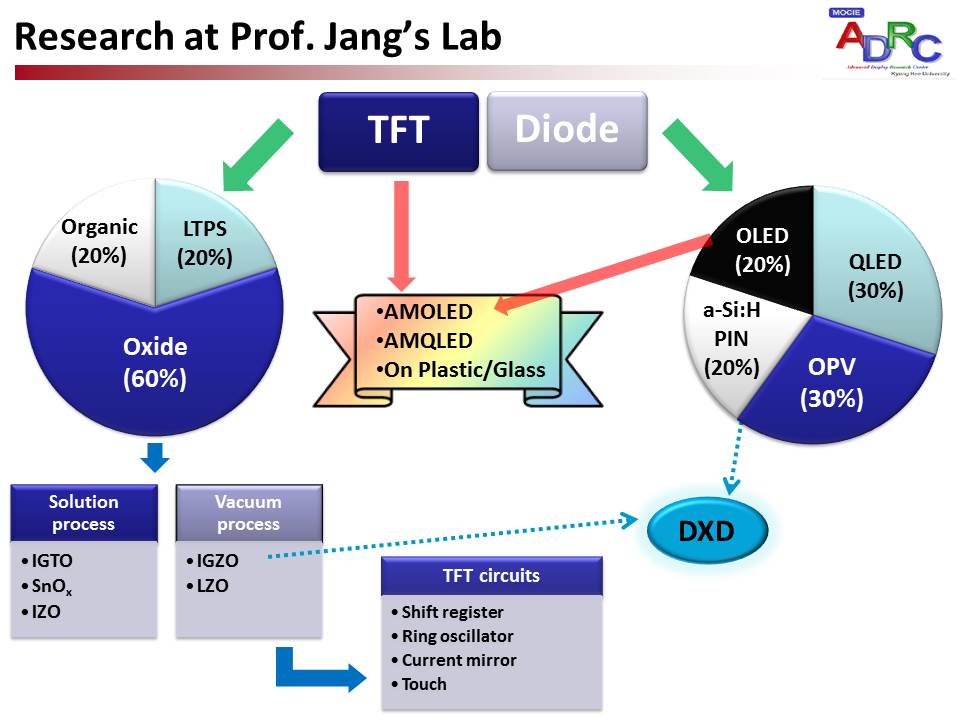

The trend in the field of displays has always been towards flexibility, transparency, high resolution, high speed, long-range uniformity, low production cost, and long-term stability – all of which depend heavily on channel materials of the thinfilm transistors (TFTs) used as pixel switching elements. Despite the success of TFT technologies that are currently dominating the display field, namely hydrogenated amorphous-silicon (a-Si:H) and low-temperature polycrystallinesilicon (LTPS), there is an active search for new and better channel materials to meet these expected future needs; of which oxide semiconductor materials are the primary candidate.

ADRC is equipped with state-of-the-art facilities used to make oxide-TFT circuits for use in active-matrix organic light-emitting diode (AMOLED) display applications. Oxide-TFTs of interest include zinc-oxide (ZnO), amorphous-indium-gallium-zinc-oxide (a-IGZO), and indium-zinc-tin-oxide (IZTO) TFTs. Some of the advantages of these oxide-based TFTs are (i) a high electron mobility, which makes it possible for the TFTs to be scaled down in size to realize displays with a high resolution, (ii) a large band gap, which makes them compatible with transparent devices, (iii) a wide process temperature range; from room temperature to 500 °C, making them suitable for use in flexible applications and (iv) the possibility to be deposited by sputtering, which makes them applicable to large area electronics.

Flexible substrate, active-matrix backplane, display mode, and thin-film encapsulation are the major issues for flexible AMOLED (active-matrix organic light-emitting diode) displays. OLED describes a specific type of thin-film display technology in which organic compounds form the electroluminescent material, and active matrix refers to the technology behind the addressing of pixels. These two combined, make AMOLEDs a competitive display technology.

At ADRC, we research to fabricate robust TFT backplanes using solution processed polyimide (PI) substrates. Since PI can withstand processing temperatures up to 420 ℃, we are able to achieve appreciable device performance. By controlling the thickness of the PI, it is possible to make rollable backplanes. The PI is first spin-coated on a glass carrier substrate, which is then detached after the TFT fabrication profcess is complete, making it possible to use very thin PI. ADRC has facilities to fabricate AMOLED displays that are up to 6”diagonal in size.

Non vacuum processing of electronic devices drives new opportunities to develop unconventional products. Among many, inkjet-printers are easy to handle, to maintain, and to fabricate electronic devices. The use of precise coating of materials through inkjet-printing also leads to both time and cost reductions as at least a photolithography step less is needed (fewer photo-mask, chemical use, and material waste). Inkjet-printing can be applied to both organic and inorganic materials on any size and material substrate.

We have developed various inorganic materials based on metal oxides semiconductors. Amorphous oxides such as zinc tin oxide, and polycrystalline indium oxide, and tin oxide have been investigated. With a maximum process temperature of 300oC, the TFTs have high mobilities exceeding 40cm2/Vs thus competing with vacuum process for applications to flexible substrates.

Highly efficient organic photovoltaics (OPVs) are now a reality with power conversion efficiency approaching 12%. The next big challenge is to enable the high-speed manufacturing of cells and modules with long lifetimes. New device architectures, new materials, and combined characterization techniques have also emerged as important drivers for progress in this technology. Reproducibly fabricating OPV devices requires an understanding of the physics associated with light absorption, the lifetime of the exciton and its transport to a charge separation interface, dissociation/recombination at the interface, the transport of charge carriers to electrodes, and charge extraction through electrode interfaces. These processes must be understood in the context of the nanoscale architecture within which they occur, which can be controlled only by understanding the role of processing conditions on the resultant morphologies produced. Moreover, the synthesis of new materials to either absorb light efficiently over a broad spectral range or better facilitate electron and hole transport has been the principal factor behind the recent steep increase in OPV efficiency. The introduction of new and more stable hole and electron extraction layers, and the understanding of the device as a whole, has enabled significant increases in OPV device lifetime. In addition, a number of combined techniques have recently emerged that can characterize structure and morphology in the bulk and at interfaces, revealing heretofore inaccessible structural details and mechanisms. These challenges span disciplines ranging from synthetic chemistry, to polymer morphology, to device architecture and physics. Their combined advances have led to a very rapidly changing field that has impacted the academic and industrial communities significantly. The establishments with Universidade Tecnologica Federal do Parana and TAKOMA Co. Ltd. have significantly contributed to the rapid growth and development of the field.

A quantum-dot light emitting diode (QLED) has emerged as an interest candidate for light source materials, since it has the advantages of good color purity (narrow FWHM) and ease of color tunability. Also, because QLED emits light from the quantum well, it has high photoluminescence efficiency. The color of QLEDs can be easily tuned color by varying the QD’s core size or the composition of QDs without changing device structure and components.

Also, QLED can be deposited by printing and spin-coating, making it a coast-effective and suitable for flexible applications. By using QDs with the different core sizes, devices with emissions over a broad wavelength range can be achieved. The color of QDs depend on their core sizes even when their HOMO and LUMO levels are the same. Therefore, we are able to tune the color by using different QD sizes in the same OLED structure. Since QDs are inorganic materials, they are more stable against moisture and oxygen as compared with organic materials.

Hydrogenated amorphous silicon (a-Si:H) technologies are wel-established for a variety of large-area applications such as solar cells, image sensors, flat panel displays and biosensors. These devices results from the a-Si:H properties such as; capability of a low temperature processing, high photosensitivity, short response time, thermal stability and high production yield. In the last decade the processing of graphic image and communication technology have been developed in both quantity and quality, with the growing demand for image sensing devices.

Especially large area image sensors fabricated with a TFT on a glass substrate can be used in a variety of image sensing applications.